Our Process

Middle East’s leading Pre-Engineered Steel Building Manufacturer !

Procedure For PEB

Uncoiling Section

Double uncoiling station with automatic loading of the coils, complete with an automatic joining system of the sheets to work continuously without line stop.

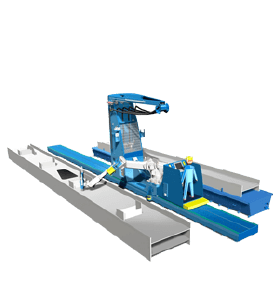

Fabrication Process

Structural fabrication can be carried out in the shop. Fabrication of steelwork carried out in shops is precise and of assured quality.

Preparation

- Plate Cutting

- Making I – Section by continuous welding.

- End plates preparation and fitting with I – Section.

- Shot blasting and application of paint.

- Packing

Structural Steel

- Procurement of steel sections.

- Cutting the section to required length.

- End plate preparation and fitting with I – Section.

- Shot blasting and application of paint.

Procedure For Cladding

Transportation

Materials are transported in trailers to job sites in the UAE and GCC. Materials are transported in containers to export regions.

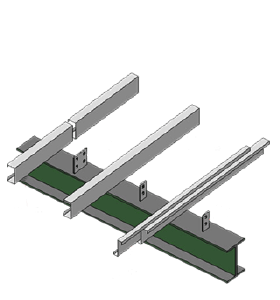

Cold Rolled Form Section

Z-Purlins and girts are manufactured by cold rolling coils of thickness 1.5mm, 1.75mm, 2mm and 2.75mm.

Final

Step 1

Uncoiling Section

Individual uncoilers for each roll former with an automatic feeding system, which facilitates coil changes without stopping production.

Step 2

Roll Forming Section

Profiling line for the sheet with cassette system for a quick setup of the production.

Step 3

Mineral Wool Section

Fully automatic line which slices the Rockwool slabs to the desired shape and fed into the production line.

Step 4

Foaming Section

A multi-component chemical station for the foam dosing and distribution unit including 30-meter double belt for mass production.

Step 5

Cooling Conveyor

The chemical reaction involved in the production of polyurethane is exothermic, for this reason the produced panel releases a large quantity of heat that should be dissipated properly before stacking to avoid deformation of it.

Step 6

Sandwich Panel

Sandwich panel line. Excellent thermal insulating properties, cost-efficient processing, light weight, and durable.