Pre-Engineered Steel Structure

Middle East's leading Pre-Engineered Steel Building Manufacturer !The pre-engineered building system is, without doubt, one of the fastest growing building systems in the world.For today and in the future, Steel has become the material of choice in building construction, compared to concrete and timber. Thus steel building designs have become more flexible and durable.

We offer single-source solutions for any building need, working with you to create a customized structure perfectly suited to your needs. From initial design work to on-site supervision to final erection, experienced designers, engineers, co-ordinators and project managers will ensure your project runs smoothly.

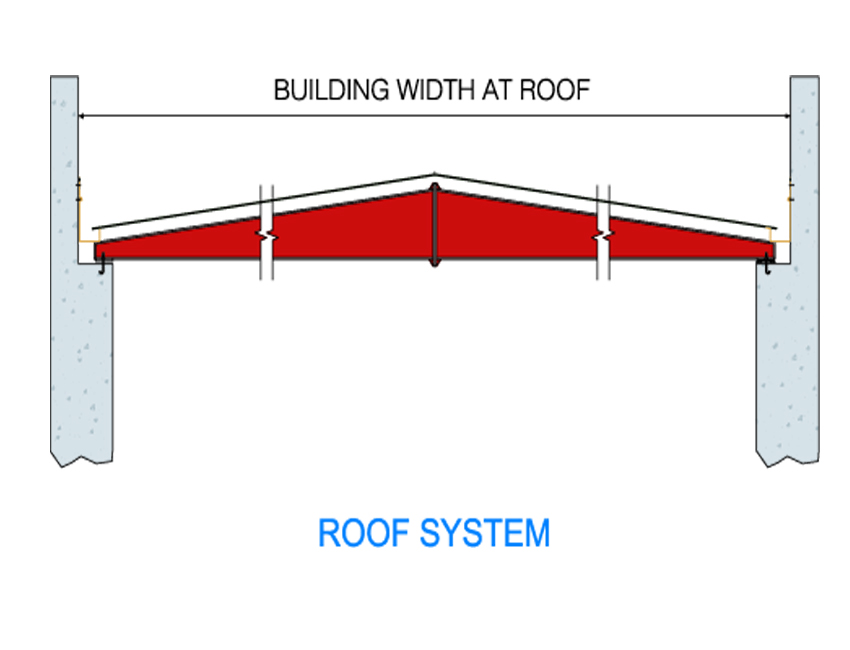

With a pre-engineered building solution, your facilities are ready for use quickly and within your budget. Pre-Engineered steel structure built over a structural concept of primary members (frames), secondary members(roof purlins & wall girts), and outer cladding. The structural members are custom designed to be lighter in weight as well as high in strength.

Pre-Engineered Steel Buildings can be fitted with different structural additions like jack beams, mezzanine systems, crane systems,roof monitors, roof extensions and canopies, fascia’s, interior partitions and roof platforms as per user requirements.

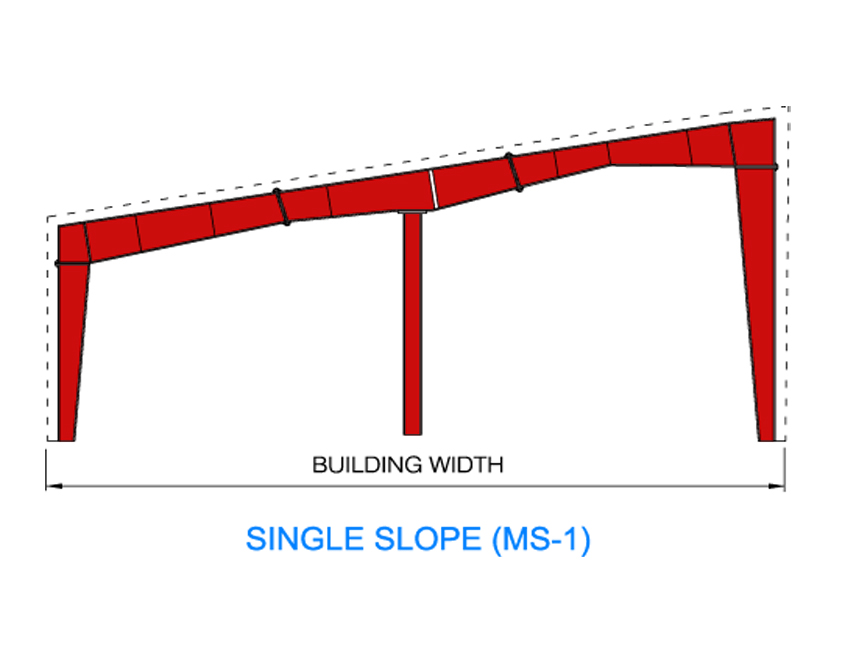

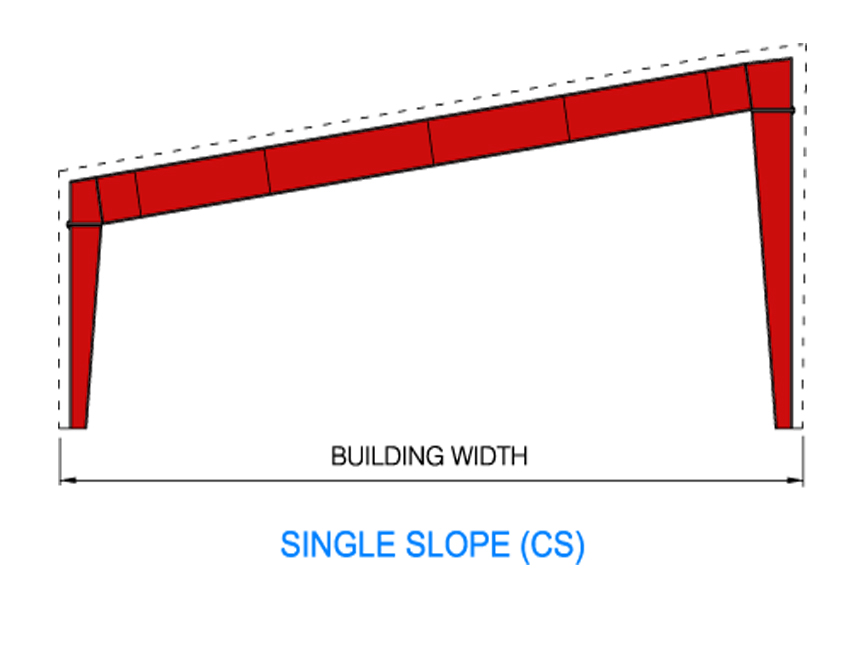

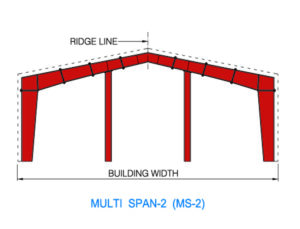

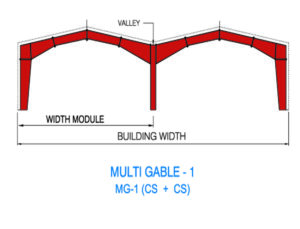

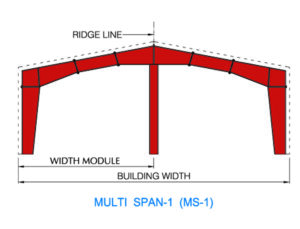

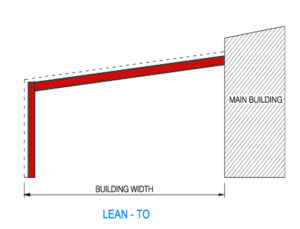

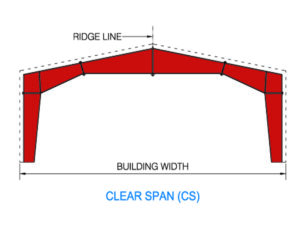

Primary Framing System

The primary frame geometry matches the shape of the internal stress (bending moment) diagram thus optimizing material usage and reducing the total weight of the structure.

Secondary Framing System

Cold formed Z and C shaped secondary structural members form the secondary, acting as supporting system for the external cladding.

Roof purlins, wall girts, eave struts, C-sections, Flange braces, gable angles and base angles are used for secondary framing.

Nesting of the secondary structural members at the frames allows them to act as continuous members along the length of the building. This doubles the strength capacity of secondary structural members at the laps where internal stress normally occur.

Secondary members have two other functions:

- Act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads

- Provide lateral bracing to the compression flanges of the main frame members thereby increasing frame capacity.

Mezzanine System

In architecture, a mezzanine is an intermediate floor between main floors of a building. The mezzanine floor often projects itself from the walls and does not completely close the view of the ceiling from the floor immediately below. In short, a mezzanine floor and the floor below it share the same ceiling. In industrial applications, mezzanine floor systems are semi-permanent floor systems typically installed within buildings, built between two permanent original stories. These structures are usually free standing and in most cases can be dismantled and relocated.

Roofing Middle East is specialized in Mezzanine system, which is frequently used in industrial operations such as ware housing, distribution or manufacturing. If you are looking for the ultimate in material handling efficiency and flexibility for manufacturing, maintenance operation and service shops Roofing Middle east can make the most of the space you have with a mezzanine system that has been carefully designed to handle your load and material flow need.

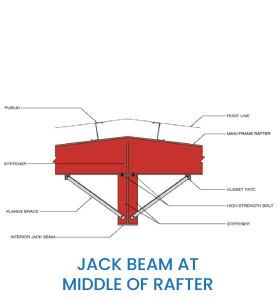

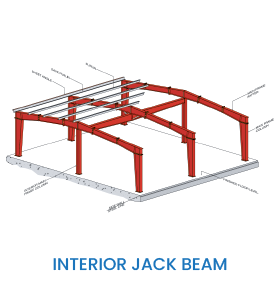

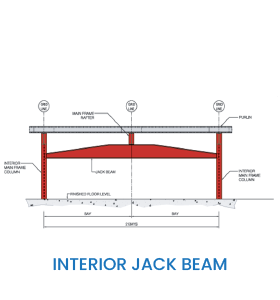

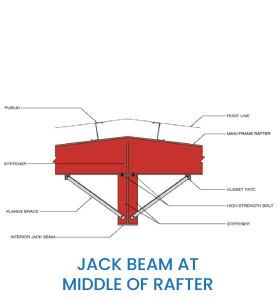

Jack Beams

The use of jack beams is an economical and safe approach for creating longer bay length when large unobstructed space is required. Common bay length (6. 7.5, 8, 9 and 10m) can be doubled with the use of jack beams making it possible to have 12, 15, 16, 18 and 20m clear bay length in areas where unobstructed space is required. In the example below the customer specified 16m bay lengths instead of the more economical 8m bay lengths. Jack beams were used in the interior of the building to make that possible. Jack beams may also be used on the exterior sidewalls in the same way.

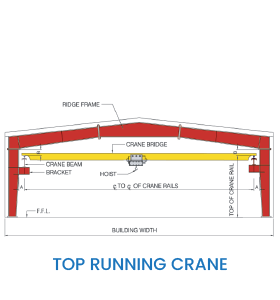

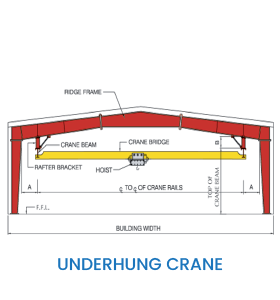

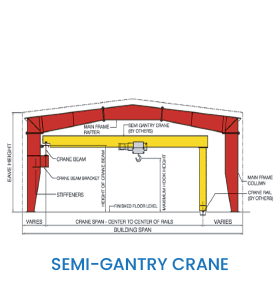

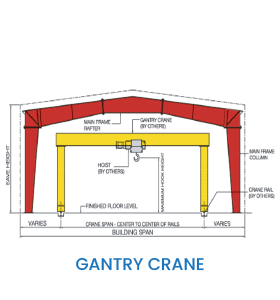

Crane System

When crane system is required, RME steel supply is limited to the supply of column/rafter brackets and the crane runway beams that support the crane system. RME design and make the estimate for the crane system after understanding the complete requirements of the customer. The most common type of crane system in pre-engineered steel buildings are, Top Running Cranes, Under hung Cranes, Monorail Cranes, Jib Cranes, Gantry Cranes, Semi Gantry Cranes etc..